How to Get Perfect Crisp and Accurate 3D Prints: A Guide by Jan Mrázek

Polymers exhibit a common trait—they shrink during the curing or solidifying process, impacting the accuracy of your 3D prints. Whether you're crafting enclosures or intricate components, this shrinkage can lead to a misalignment between design intent and physical output. In this exploration, Jan Mrázek dissects polymer shrinkage, assessing its significance, exploring additional sources of inaccuracy, and uncovering methods for precise measurement and compensation.

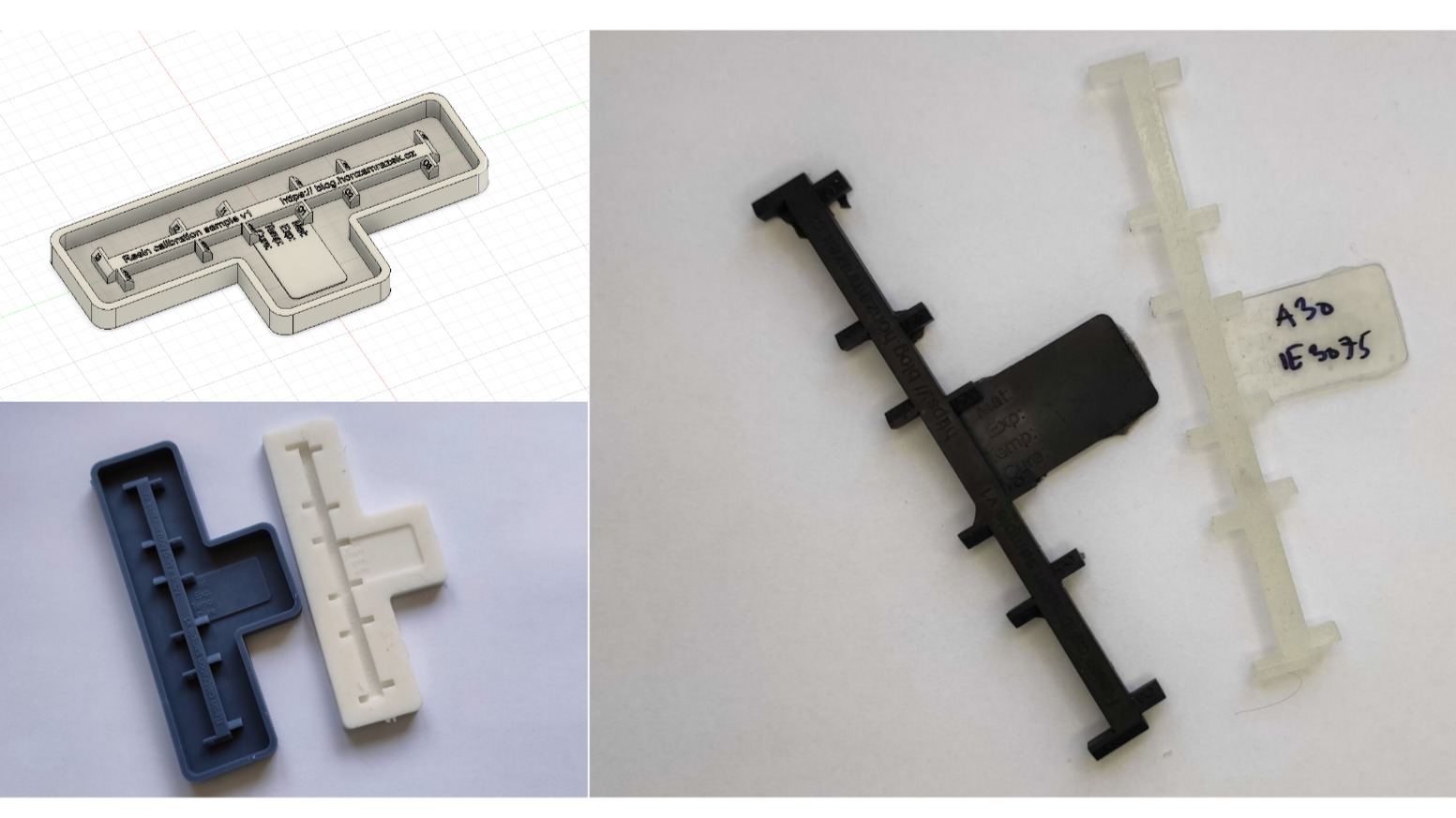

When printing a standard 35mm test cube on a resin printer and measuring it precisely, you may find discrepancies in dimensions. Several factors contribute to these inaccuracies:

- Squeezing out Resin

- Resin Shrinkage

- Exposure Bleeding

For silicone molding and similar applications, a detailed pattern aids in evaluating overall process shrinkage. Z-direction shrinkage in casting, distinct from printing, requires separate compensation.

In the realm of measurement compensation, six precise measurements, along with understanding linear equations and statistical analysis, contribute to accurate calibration.

Regarding resin characteristics, most show linear shrinkage between 0.3–0.6%, and volumetric shrinkage at 0.9–1.8%. Exposure bleeding varies; darker resins bleed less, while outliers like Siraya Tech Fast Mecha may need special compensation.

Ongoing experiments scrutinize the constant nature of shrinkage, exploring variables like time and temperature during curing. Jan aims to empower resin enthusiasts to navigate and master the intricacies of dimensional accuracy in 3D printing as they unravel these complexities.

Click here to read the Original Blog and learn more about "Getting Perfectly Crisp and Dimensionally Accurate 3D Prints on a Resin Printer".